![]() 1-800-Simpson

1-800-Simpson

How They're Made

No one makes a wood door like Simpson. From standard construction methods to doors engineered specifically for tough exposures, learn what makes these doors better.

Engineered Construction

Simpson uses a variety of innovative techniques to build the best doors. And while there are a number of ways to build a stile and rail wood door, Simpson believes in the enduring quality of a door with engineered stiles. What does that mean? It means your door's stile components, the longest components in the door, are made of multiple pieces of wood rather than a single piece of wood. This adds strength and long-lasting quality while looking exactly as if they were constructed from a single piece of wood.

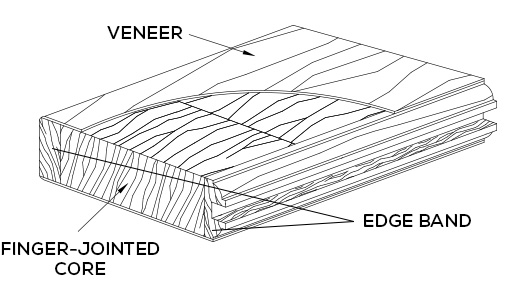

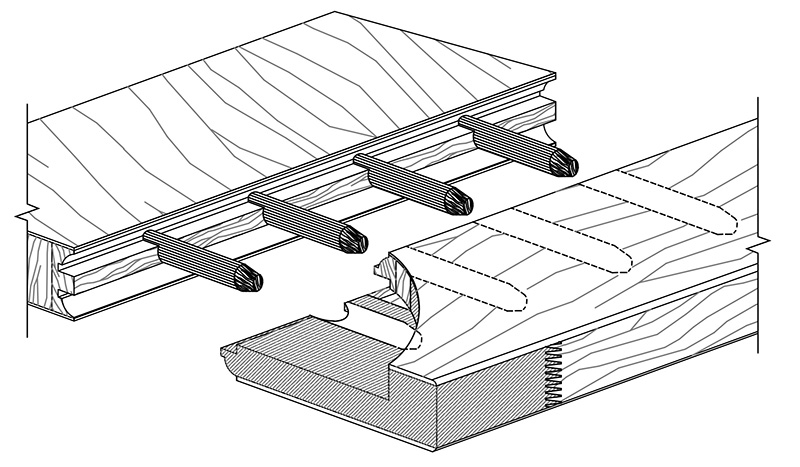

Finger-Jointed/Wood Core

The all-wood core in a Simpson stile provides incredible strength and durability. And all components in the core are finger-jointed, not edge glued. Finger-joints are superior joints as they have greater gluing surface for added strength.

Outer Edge Band

The outer edge band blends with surface veneers so that the finger-jointed core is not visible.

Inner Edge Band

Inner edge bands are provided so that no finger-joints show in the sticking.

Surface Veneer

Specially selected vertical grain cants are sliced for the stile and rail faces. The cants are run through a hot water bath to soften the wood fibers to obtain a smooth slice without tearing the grain. The resulting veneers are dried to a similar moisture content as the core material. By using these selected veneers, surface quality is enhanced.

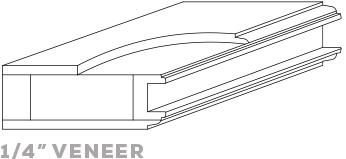

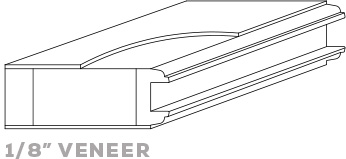

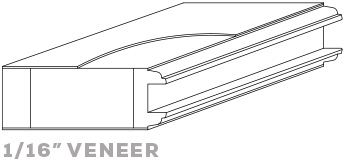

Simpson knows that different projects call for different veneer thickness. As a standard, Simpson uses thick 1/16" veneers for all wood species. This thickness allows for multiples refinishes over the life of the door.

For projects that require a thicker veneer, consider 1/8" or 1/4". Simply let your Simpson door supplier know your project requirements up front and we can build exactly what you need.

Dowel-Pinned Stile and Rail Joinery

All stile and rail joints are secured using dowel pins. Each fluted dowel is glued securely into the bore within both the stile and rail components. Further, the cope on the stile and rail components ensure a secure, flush joint, and creates a beautiful appearance.

In the case of doors with Simpson's patented UltraBlock® or WaterBarrier® technologies, the entire coped end of all rail and stile components undergo the Weather Seal™ process, where all surfaces are coated with glue. This further ensures virtually no possibility of stile and rail separation or water infiltration. And exactly the type of innovation you would expect from Simpson.

For an optional stile and rail joinery method, please see the Nantucket Collection®

Copyright © 2025 Simpson Door Company. All rights reserved.